An inside look at 60 years of the St. Lawrence Project

Looking across the Robert H. Saunders St. Lawrence Generating Station towards the New York Power Authority’s Franklin Delano Roosevelt St. Lawrence station. The two high structures are gantry cranes that travel on tracks for generator maintenance. The square covers are the tops of the generator units. Photo: James Morgan

A symbol of the Seaway

The average person does not usually get to see inside the Robert H. Saunders St. Lawrence Generating Station. That’s the name of the Canadian half of the hydroelectric dam that spans the St. Lawrence River across the Canada-U.S. border between Cornwall and Barnhart Island near Massena. Since 9/11, tours of the actual station have been strictly limited on both sides and visitors were usually limited to the visitor centers on either side. But, it’s the 60th anniversary of the station this year and to celebrate, the plant was open for free guided tours last Saturday. It was a great opportunity to get a close look at one of the biggest and enduring results of the St. Lawrence Seaway and Power Project.

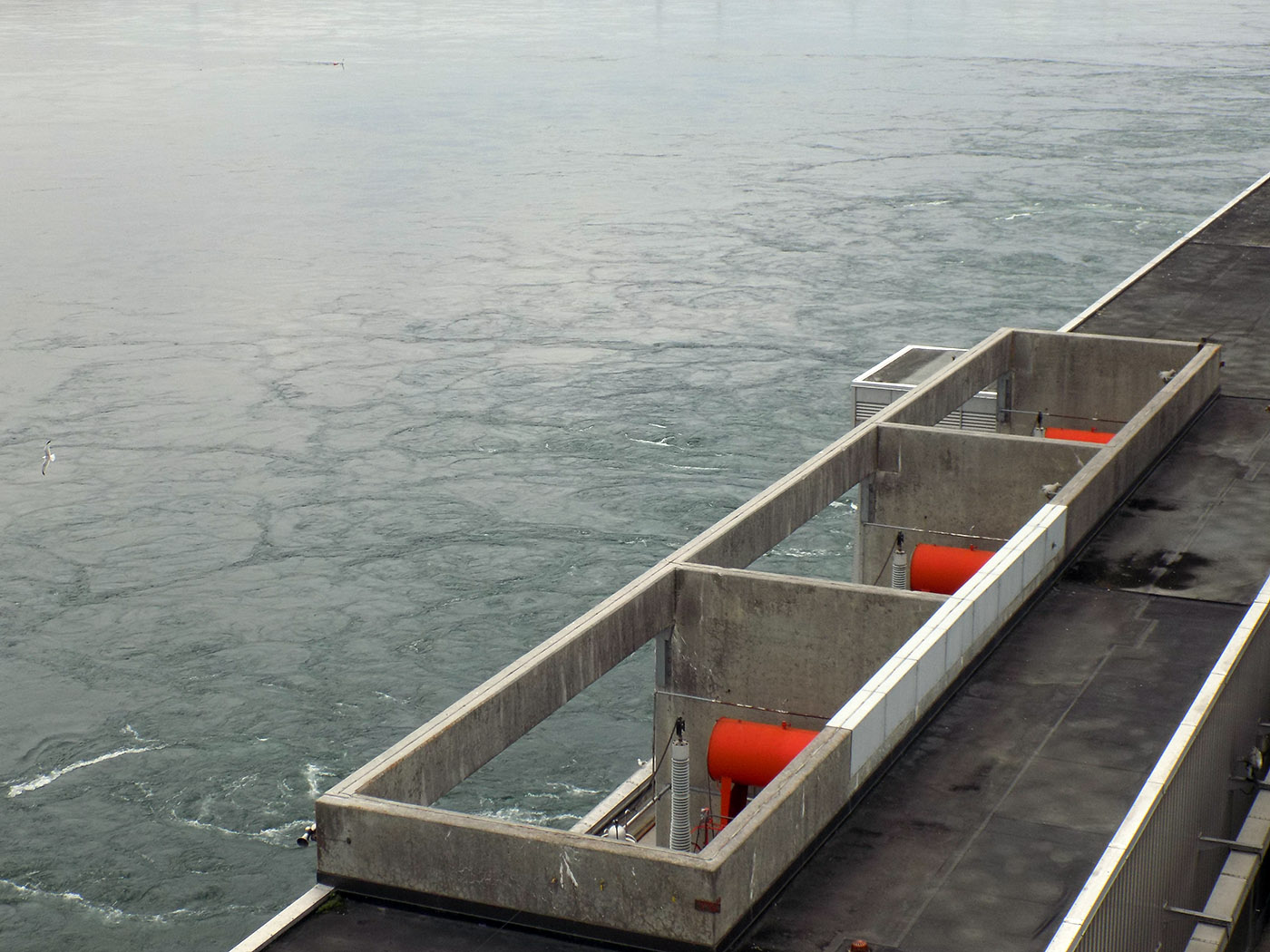

These giant transformers send the electricity generated at the St. Lawrence project into the power grid. The transformers on the Ontario side of the dam are orange. They’re gray on the New York side. Photo: James Morgan

Powerful facts

The station is named after Robert Hood Saunders, who was Chairman of the Hydro-Electric Power Commission of Ontario (Ontario Hydro) from 1948 until his sudden death in an airplane crash in 1955 at age 51. There are 16 generator units in the plant with a total output of 1,045 megawatts, enough to power a city of about 750,000 people or about 5% of Ontario’s power needs. Saunders produces a bit more electricity than the half of the dam owned and operated by the New York Power Authority. It also has 16 generators but the total output as around 820 megawatts, which the power authority says can supply a city the size of Washington, D.C. About 90 people work at the Saunders station, which has been owned and operated by the provincially-owned Ontario Power Generation (OPG) since 1999. Many of them volunteered on Saturday as tour guides. Some even brought their spouses and children along, too. I grew up in an Ontario Hydro household, and the family atmosphere reminded me of similar events in my past.

Plant Manager Brent Stajkowski leading a tour on the upper level of the station. Photo: James Morgan

A dam tour

My tour guide was Brent Stajkowski, the Plant Manager. We started in the marble-walled lobby of the station and then went upstairs to the expansive open room that was the original visitor center. Today, it’s home to the control room where operators not only oversee the Saunders station, but they also remotely control every other OPG hydroelectric station in eastern Ontario.

The head, or height of water flowing through the turbines at Saunders is only 80 feet/24.3 meters, but the water is moving fast enough to generate a large amount of electricity. The churning, bubbling water at the dam’s outflow or tailrace looks relatively calm, but Stajkowski said the aerated water makes it less buoyant, any boater or swimmer who ventures into it is certain to be sucked under and drown.

There are a few unique features of the St. Lawrence power project. The tops of the generator units are not under a roof in an enclosed powerhouse. Instead, they’re the “California Design” where they were covered by retractable steel covers. Stajkowski said the design works well in California, but it’s a challenge with all the ice and snow of a local winter. A crew works full time to keep the area clear during the winter months. Most hydroelectric dams also have trash racks that collect debris, but the St. Lawrence project does not have them. The river is so full of debris that if the dam had trash racks, they would fill up quickly and reduce the productivity of the generators. So, the stray vegetation and springtime wreckage of boat docks instead freely flows through, getting chopped up like coleslaw in the propeller turbines. Another unique feature is the eel ladder. To conserve the American eel population, a special ladder was installed that bypasses the dam for eels to swim through. It wasn’t open on tour day, but some of the slithery swimmers were on display in a small aquarium.

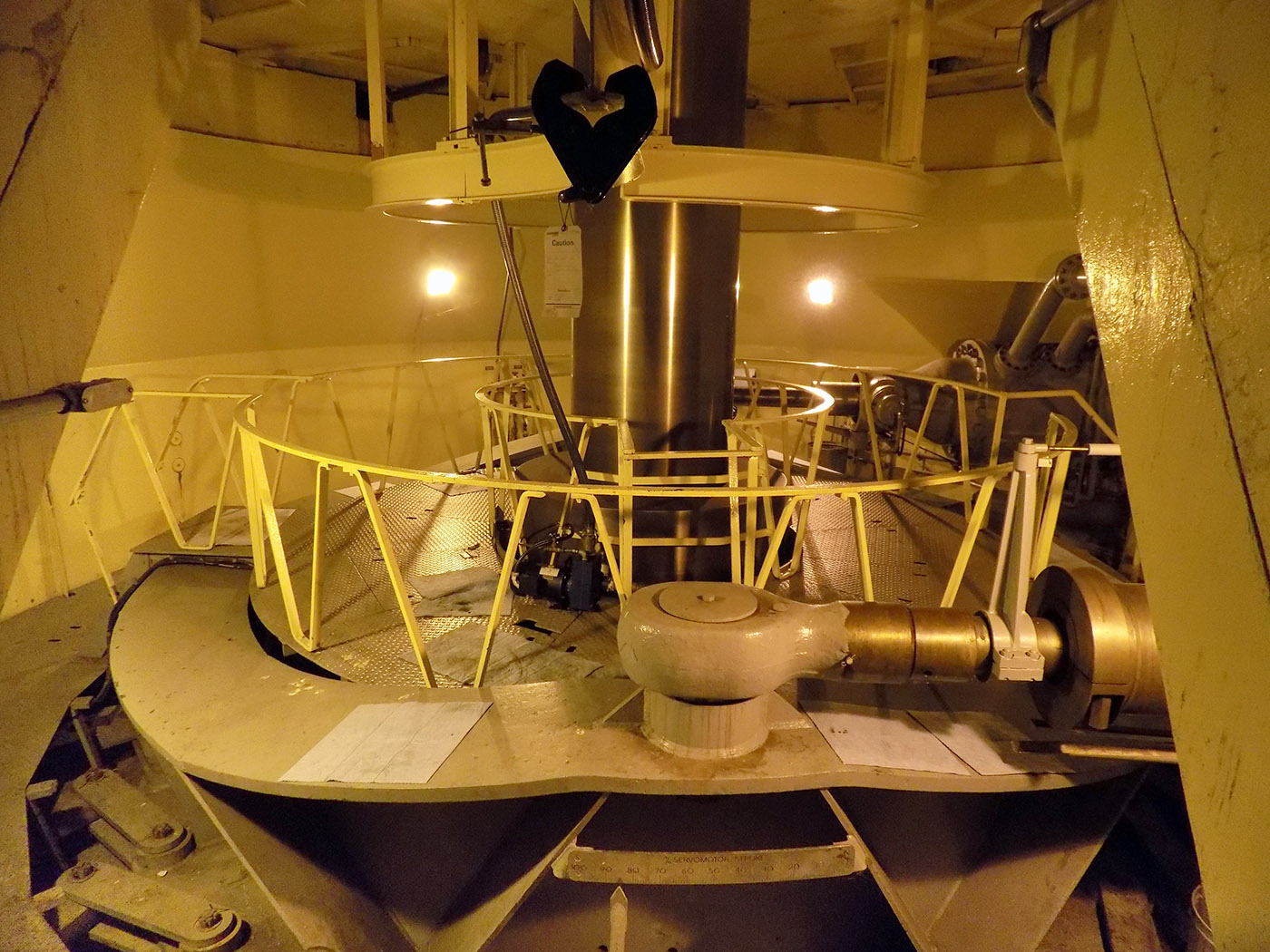

A spinning turbine shaft. The object in front of the railing is one of the servo motors that control the speed. Water is rushing through the propeller turbine below. The generator unit is above. Photo: James Morgan

Tour groups got to go down in the depths of the station, too. Senior Plant Engineer Keith Eastman showed us inside the cramped, hot space where a turbine shaft was spinning around and the Servo Motors that control its speed. Brent Stajkowski pointed out a long expanse of scaffolding in the area below the generators. He said it is there as a safety precaution due to expanding concrete. The aggregate (sand and gravel) used when the dam was built has caused a chemical reaction that makes the concrete expand. Work is ongoing to repair the problem, which has also affected other hydroelectric dams in Canada. The New York Power Authority did not use the same aggregate on its half of the St. Lawrence Project, so they do not have to deal with the same situation.

The row of governor control units for each generator. The scaffolding is a temporary measure while work is done to reduce concrete expansion. The tricycle is one of many ways plant employees travel around the large facility. This photo was taken looking south from unit 1. Photo: James Morgan

There was also a demonstration of how the station’s two giant gantry cranes work. Both have a glass compartment an operator can sit in, but their hoists can also be operated with remote control. Visitors got to try moving lead weights from one trash can to another using the hoist and a remote control device.

Cooperation on the border

OPG and the power authority have an agreement where they can share equipment and staff at the St. Lawrence Project without any of the people or objects having to go through border security on either side, if the people and items are needed for a task within the plant. A transmission line crosses the river in front of the station so that power can be sent back and forth between Ontario and New York. Ontario also has the right to “wheel” power across the power authority’s lines to other American utilities. While national governments bicker about tariffs and trade, the production and flow of electricity, goods, and people is working perfectly fine at the provincial and state level over the St. Lawrence River in our own region.

The International Friendship Monument stands at the Canada-U.S. border on the St. Lawrence Power Project dam. Photo: James Morgan

Tags: canada, Cornwall, hydroelectric power, New York Power Authority, Ontario, Ontario Power Generation, Robert H. Saunders St. Lawrence Generating Station