New Hampshire company wins wood stove contest

Last month a contest was held on the National Mall in Washington DC, to evaluate different wood stoves for best efficiency. An organization called the Alliance for Green Heat sponsored the “wood stove decathlon.”

The display is gone. But you can read more about the 14 finalists, from across the U.S., Europe and even New Zealand. The winner for over-all performance – and affordability – was Woodstock Soapstone Company of West Lebanon, New Hampshire.

Popular Mechanics interviewed Woodstock’s Tom Morrissey about the hows and the whys of seeking better efficiency:

“Philosophically, the economy has not been kind to millions of people over the last six years. Many people use wood heat because they have to, not because they want to. Often these people use wood as a primary heat source and burn the most wood on a per-capita basis. Anyone who wanted to clean up wood burning would start from the bottom and work their way up.” (excerpt from longer Q & A)

“It’s a combination of low tech and high tech,” said James B. Meigs, one of the judges. “It’s a humble area that doesn’t get enough attention.”

And there’s plenty of room for improvement. According the the Times article:

Wood stoves typically deliver only 40 to 50 percent of the energy potential of the wood in the space they are supposed to heat. Some of the models in the competition deliver more than 90 percent and make the smoke cleaner. In wood stoves, cleanliness and efficiency turn out to be the same thing.

“If you can see it, if you can smell it, that’s energy that isn’t heating your house,” said another judge, Philip K. Hopke, a professor at Clarkson University and the director of the Institute for a Sustainable Environment there. Parts of the smoke that can be smelled or seen are particles and gases that failed to burn, Professor Hopke said.

The contest came with a prize of $25,000. In a nice touch, Morrissey shared the prize with two other entrants who’d participated on a shoestring budget.

Perhaps it’s not possible to build wood stoves that are 100% efficient and many of us already have an existing unit that will remain in use for years to come. But it’s good to know that better models are being developed to extract more heat, reduce pollution and expand choice. Efficiency just makes sense.

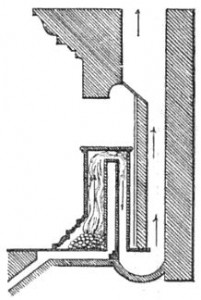

An early attempt to improve efficiency: “The Franklin stove. Cool air enters the baffle through a duct under the floor. Smoke exits through a U-shaped duct in the floor.” Source: Wikipedia

Tags: Alliance for Green Heat, energy, environment, science, wood fuel, wood stoves, Woodstock Soapstone Company

Good, clean-burning, efficient wood stoves are an un-recognized, and under-appreciated part of the solution to our atmospheric carbon problem. Many see another chimney as another contributor to climate change, but exactly the opposite is true.

An oil or gas powered furnace, burns ancient, or pre-historic carbon. These deposits of coal, oil, and gas were created millions of years ago, on a very different planet than the one we enjoy today. These carbon deposits were entombed in ancient sea-bed layers, and the result has been a leaner, drier, and cooler place to live. If we burn all of the fossil fuels we can find, we will return to that stinking jungle that the dinosaurs once roamed.

By contrast, my wood stove uses fuel from the current era, and the carbon effluent returns to the current era.